Novel Methodology for Reproducibility of OLED Lifetimes and Identification of Killer Impurities

For reproducible OLED performance, it is crucial to maintain an accurate deposition rate throughout the vacuum thermal evaporation processes. For this reason, we developed a custom design crucible. With the new design crucibles, we achieve very small run-to-run variation in the deposition thicknesses, typically controlled within ±1 %.

A conventional VTE without automation is subject to a large fluctuation in the OLED lifetime because the fabrication time varies day-by-day, and the credibility of the lifetime data is questionable. We ensure the reproducibility of lifetime performance by utilizing an automated VTE system so that the fabrication time can be properly and constantly regularized. Thus, we see only marginal run-to-run variation in the OLED lifetime.

Recently, we have developed methodologies that are useful for our customers to solve lifetime issue. We attached a new customized chamber to the VTE system. The aim is to perform intentional in-situ impurity exposure to specific organic interfaces during an OLED fabrication. We can also study on the impact of water present in a vacuum chamber. For this purpose, a cryotrap is equipped to the exposure chamber, which can reduce the amount of baseline water.

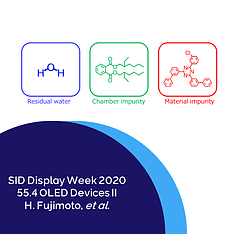

We believe that the method will benefit our customers who want to solve specific lifetime issues by distinguishing or by combining different factors: residual water, chamber impurity, and material impurity.

For more details, please check our YouTube video.

SID Digest of Technical Papers 51, 822-825 (2020)