OLED and QLED Background Capability to Meet Customer Demands

In-house device characterization

- Sputtering

- UV lithographic mask aligner

- VTE and plasma enhanced CVD system

- Light distribution/integrating sphere

OLED lifetime killer identification

- Customized chamber to examine the impurities

- Long-term VTE runs mimicking mass

- OLED lifetime measurement

- HPLC/TG-DTA/TOF-SIMS, etc.

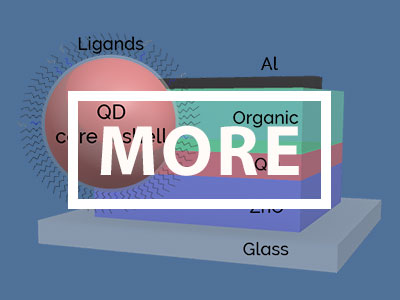

Validation of QLEDs and perovskites

- Size dispersion and film quality control

- Cd-free QLED evaluation

- EQE and lifetime reproducibility

- Cross-sectional TEM, SEM-EDX, etc.

Toward Soft Electronics and XR Applications

Barrier and micro-structuring

- Low temperature (60℃) CVD

- Thin-film encapsulation

- Stepper lithography and dry-etching